MATERIALS

We produce premium stainless damascus steel and titanium damascus composites for knifemakers, watchmakers, jewelry makers, pen makers, and other artists. Highly controlled production process and metallography analyses helps us to provide the best quality for our customers.

HardCORE

cored stainless damascus steel

MAGNA core

ELMAX core

CPM154 core

AEB-L core

Stainless

stainless damascus steel

CONTRAST

MARTENSITE

AUSTENITE

Rainbow

titanium damascus and composites

Rainbow-Zr

Rainbow-Ti

Rainbow-Nb

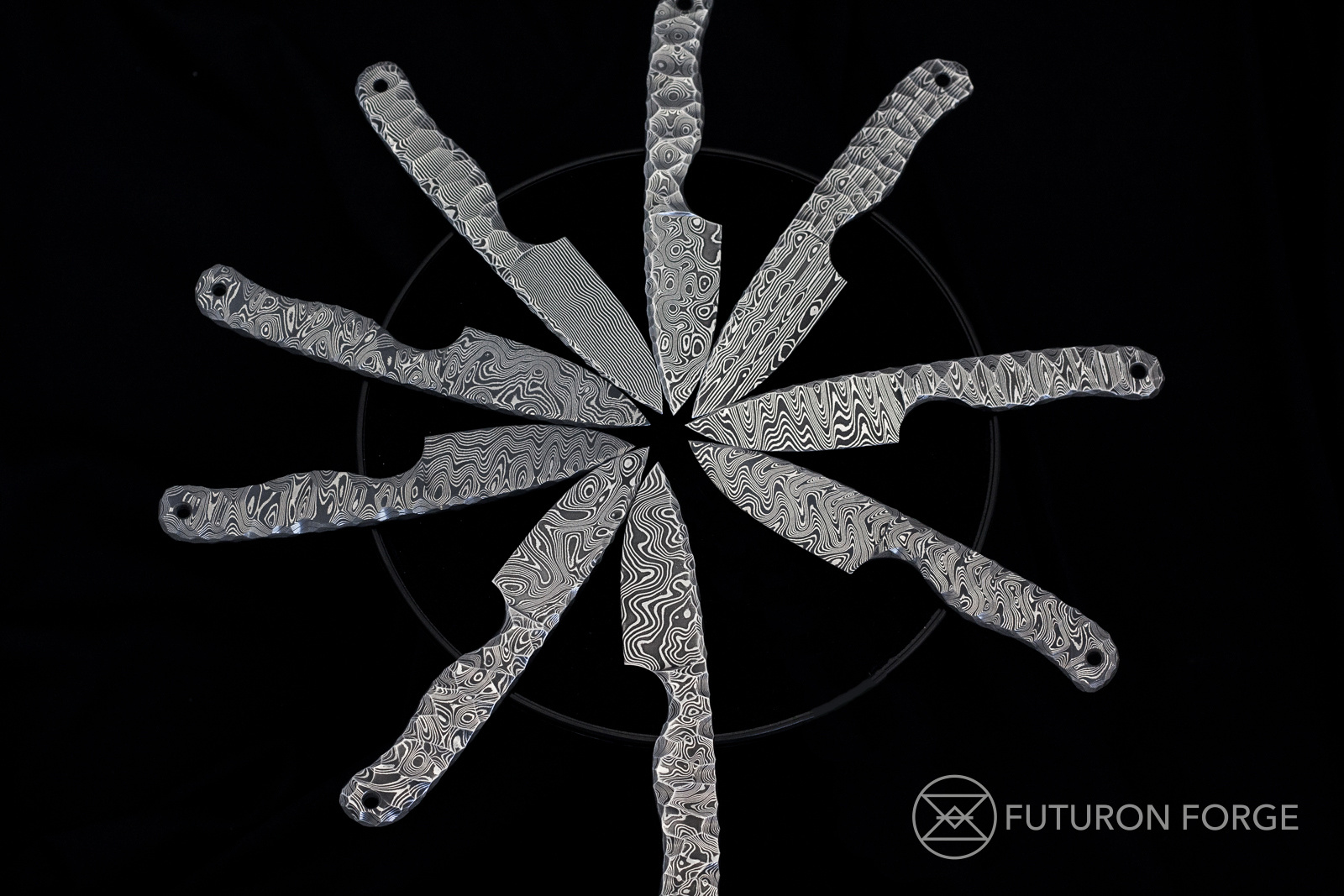

HardCORE

#HardCOREfuturon is stainless damascus steel with MagnaCut, Elmax, CPM154 or AEB-L cores. MagnaCut, Elmax and CPM154 are high-end powder steels with an excellent grain structure and properities. Sides from austenitic-martensitic damascus make an excellent contrast between the layers. #HardCOREfuturon damascus excels in high visual contrast, together with corrosion resistance, sharpness and durability. We produce this material in different patterns, soft annealed for smooth processing. We produce 3.1 mm – 8 mm (.125 – .310 in) thickness billets. This material is suitable for all knives or cutting tools where you require extreme durability and aesthetic qualities.

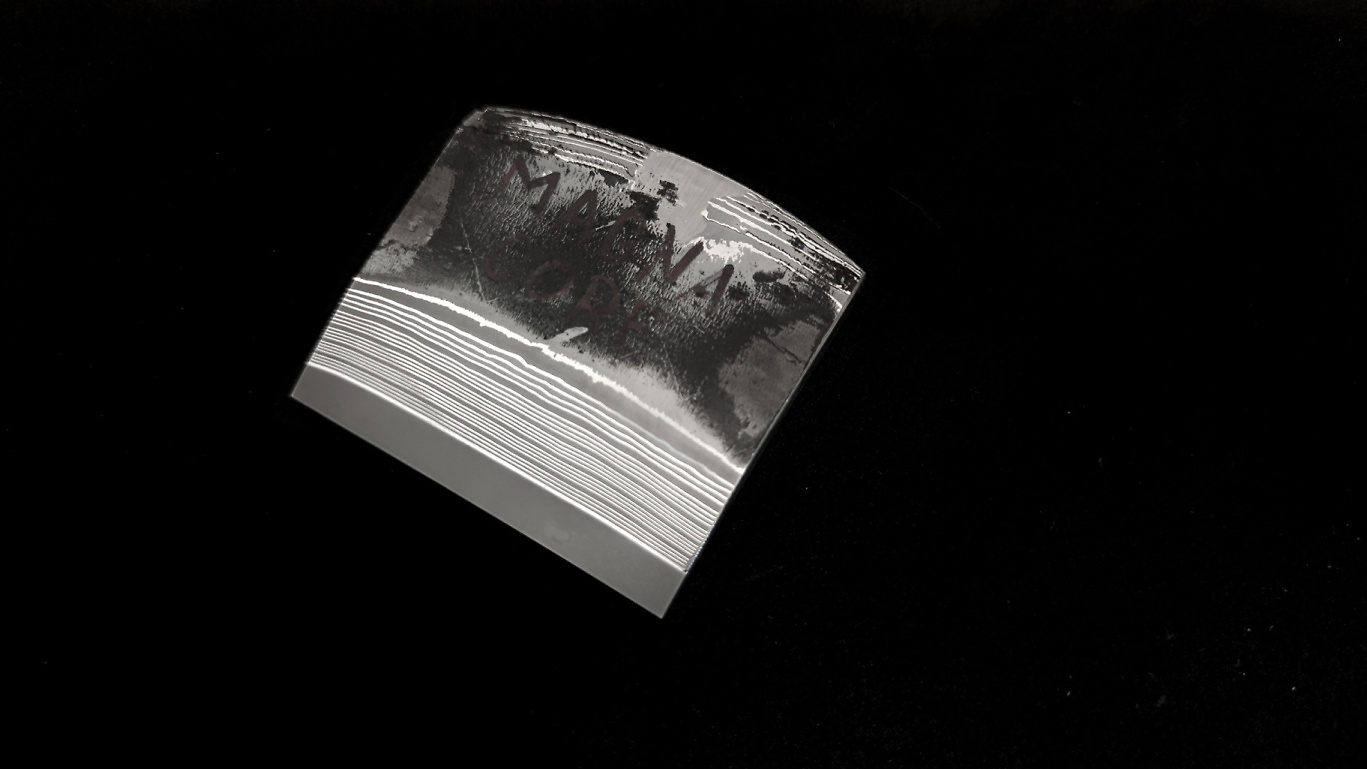

MAGNA core

Stainless Damasus with Crucible MagnaCut core. MagnaCut is a groundbreaking American-made powder metallurgy stainless steel for knives. An excellent combination of toughness and wear resistance makes it a great choice for small folders, choppers or kitchen knives.

- San-Mai layered MagnaCut core stainless Damascus

- Composition of outer layers: AISI304 + AEB-L steel

- Soft annealed

- High contrast etching

- Hardenable up to 61 HRc

- Ultimate for knife blades and other cutting tools

- Marking: “FF MAGNA core”

- Hashtags: #HardCOREfuturon #FFMAGNAcore

![]()

ELMAX core

ELMAX Superclean by Uddeholm is powder steel with an excellent grain structure, providing great wear resistance, corrosion resistance, and dimensional stability.

- San-Mai layered ELMAX core stainless Damascus

- Composition of outer layers: AISI304 + AEB-L steel

- Soft annealed

- High contrast etching

- Hardenable up to 61 HRc

- Best for knife blades and other cutting tools

- Marking: “FF ELMAX core”

- Hashtags: #HardCOREfuturon #FFELMAXcore

![]()

CPM154 core

Stainless Damasus with CPM-154 core. CPM-154 is a premium American-made powder metallurgy stainless steel for knives. It is rich in carbides, Chrome and Molybdenum. This composition reaches silver-shiny core.

- San-Mai layered CPM154 core stainless Damascus

- Composition of outer layers: AISI304 + AEB-L steel

- Soft annealed

- High contrast etching

- Hardenable up to 60 HRc

- Great for knife blades and other cutting tools

- Marking: “FF CPM154 core”

- Hashtags: #HardCOREfuturon #FFCPM154core

![]()

AEB-L core

AEB-L is martensitic stainless steel with a fine grain microstructure developed for razors and surgical scalpels. AEB-L provides good wear and corrosion resistance.

- Composition of outer layers: AISI304 + AEB-L steel

- San-Mai layered AEB-L core stainless damascus

- High contrast etching

- Soft annealed

- Hardenable up to 61 HRc

- Great for knife blades, razors

- Marking: “FF AEBL core”

- Hashtags: #HardCOREfuturon #FFAEBLcore

![]()

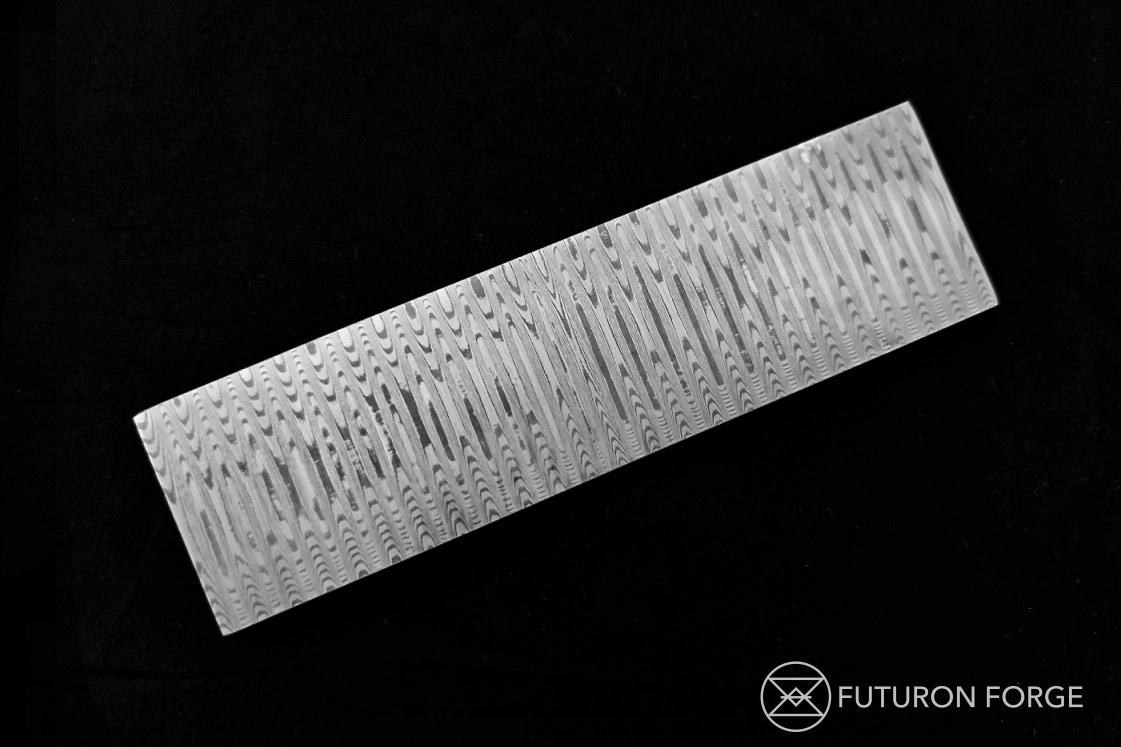

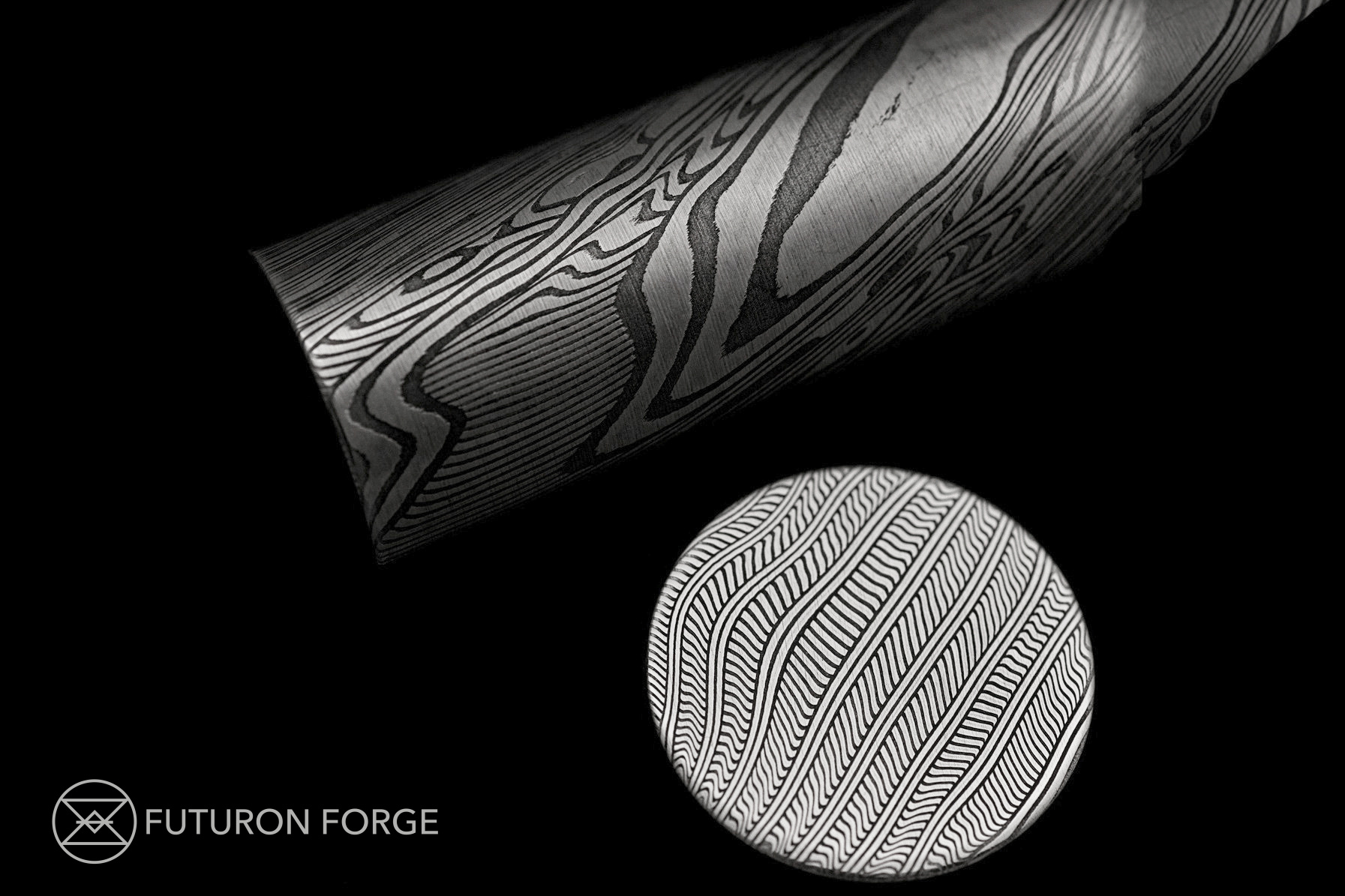

Stainless

#StainlessFuturon is a non-corrosive damascus steel produced in variety of pattens and layerings, soft annealed for smooth processing. Number of damascus layers ranges between 100-350 layers. We produce billets in 3–8 mm (.118 – .315 in) thickness and rods in ø18-45 mm (0.7 – 1.7 in) diameter.

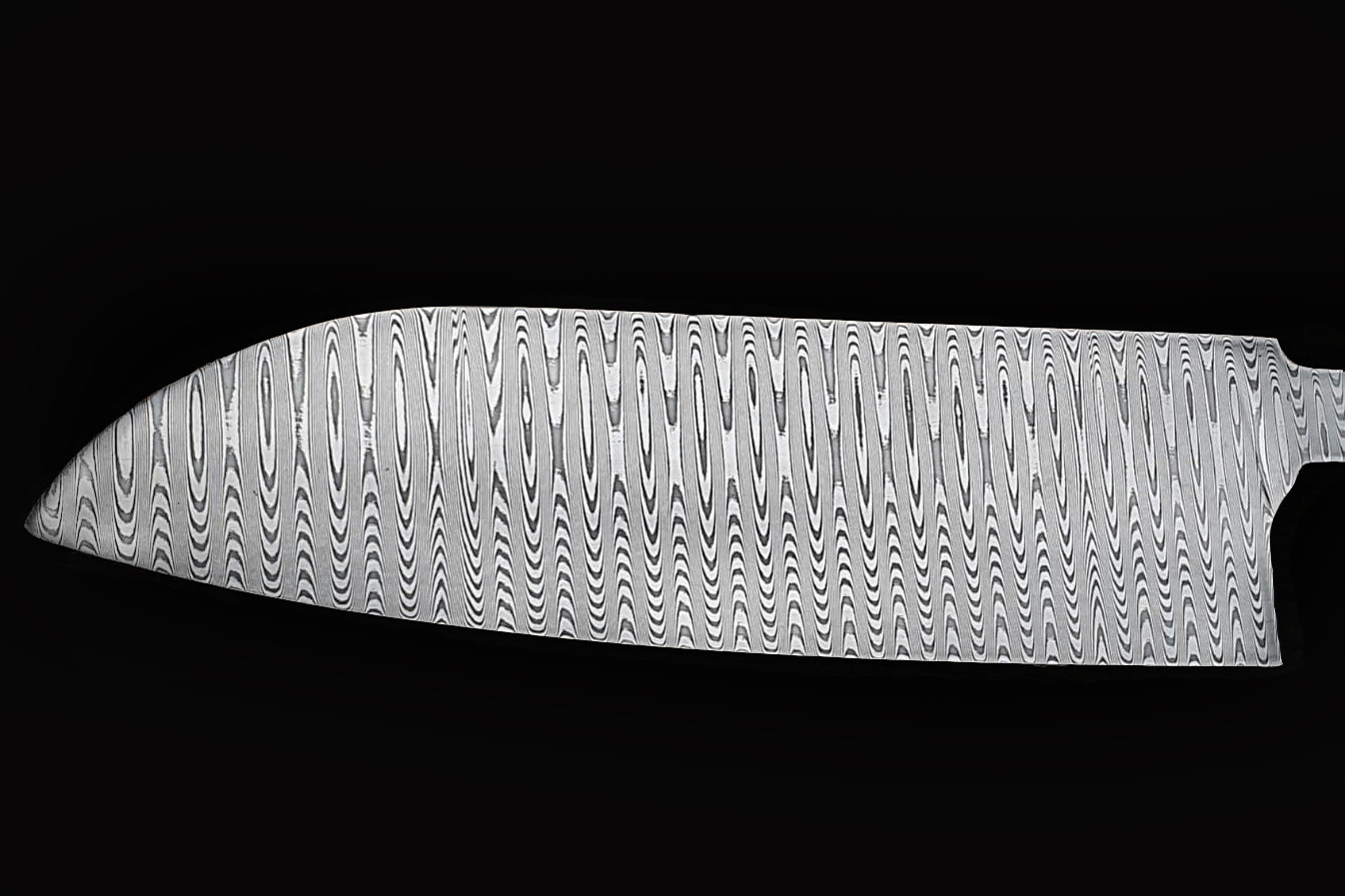

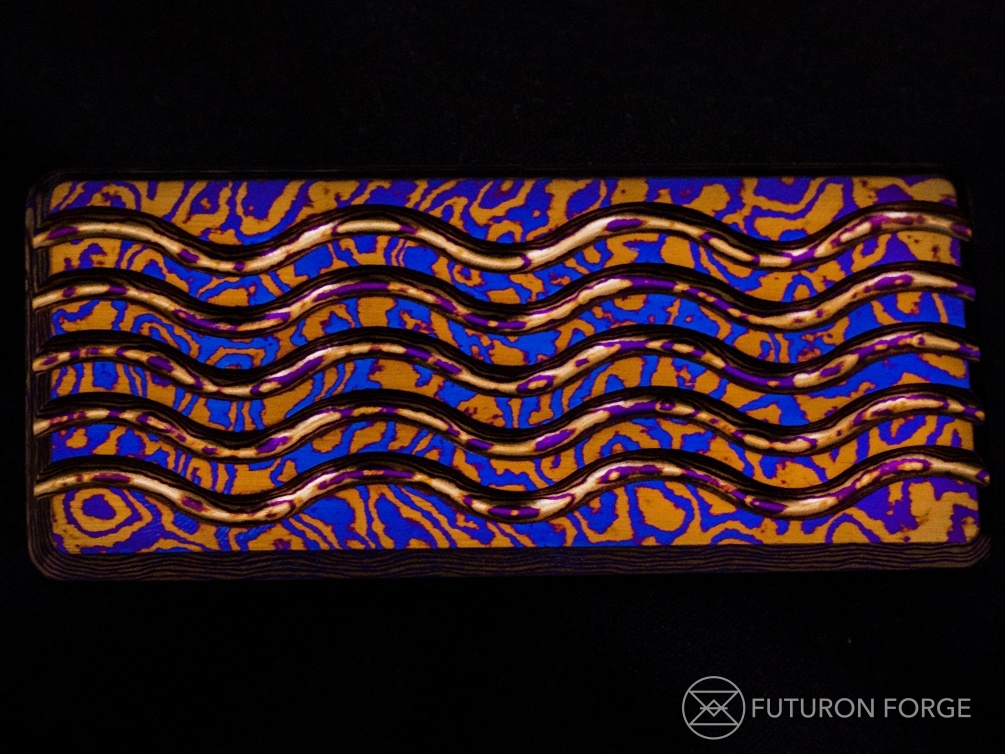

CONTRAST

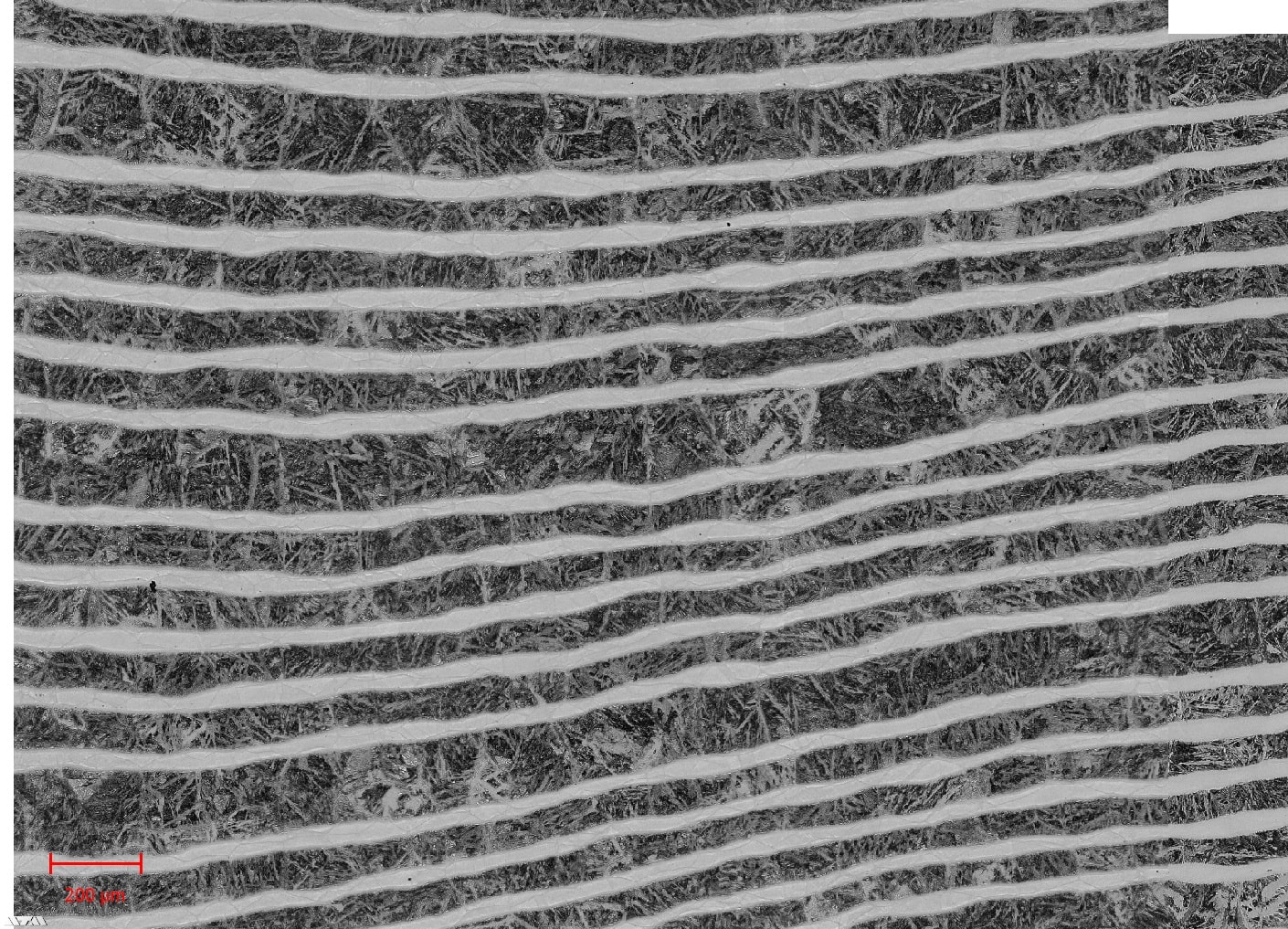

#FFCONTRAST is stainless damascus steel with a high contrast (shiny-silver/black). The common mixture ratio varies from 3:1 to 2:1 (martensitic AEB-L : austenitic AISI 304).

- Composite of AEB-L + AISI 304 steel

- Soft annealed

- Requires heat treatment

- AEB-L is hardenable up to 61 HRc

- High contrast etching

- Great for knives, bolsters, jewelry, watchcases, pens, or artwork production

- Marking: “FF CONTRAST”

- Hashtags: #StainlessFuturon #FFCONTRAST

![]()

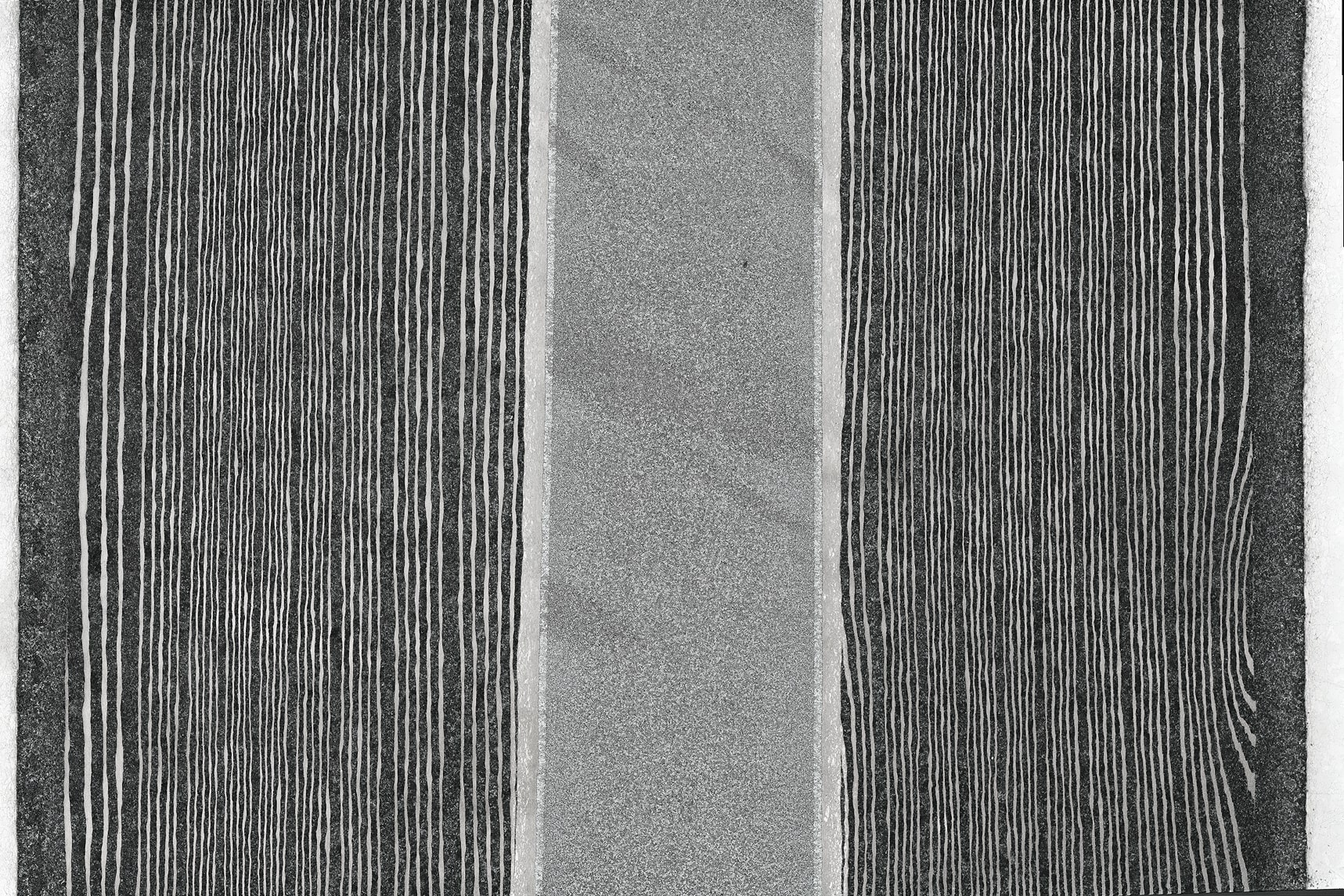

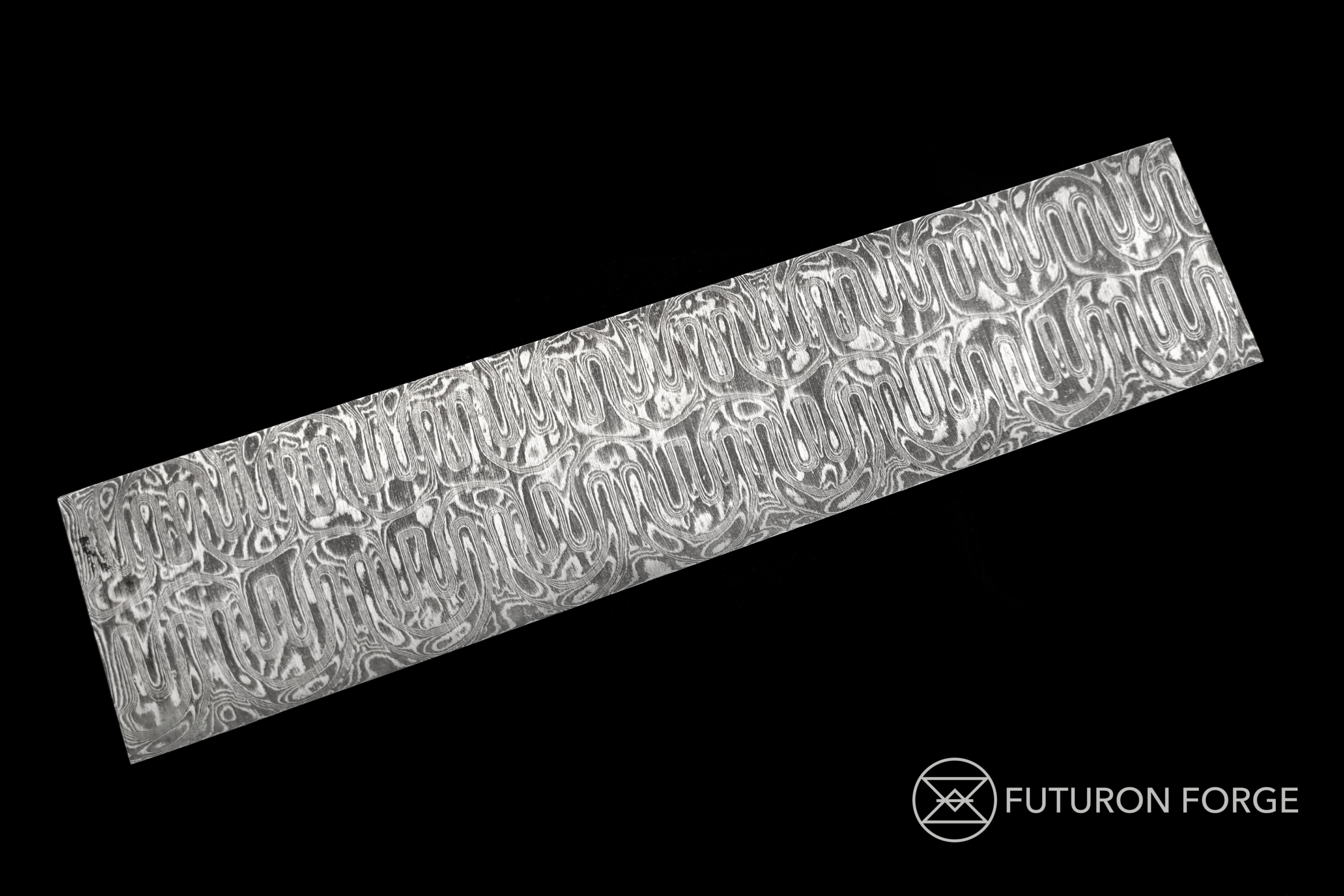

MARTENSITE

#FFMARTENSITE is stainless damascus steel combining two high-performance martensitic steels by Uddeholm with good corrosion resistance, excellent cutting abilities and excellent toughness.

- High-performance martensititc stainless Damascus

- Composite of UHB AEB-L and UHB SS716

- Soft annealed

- Hardenable up to 61HRc

- Nice grey-silver/black contrast

- Best for high-end knives (kitchen, hunting, folding)

- Marking: “FF MARTENSITE”.

- Hashtags: #StainlessFuturon #FFMARTENSITE

![]()

AUSTENITE

#FFAUSTENITE is stainless damascus combining two austenitic – non hardenable steels. Both components exceed in low volume of Nickel. This material is easily processable.

- Composite of austenitic stainless steels AISI 304 + AISI 316

- Non-hardenable

- No heat treatment is necessary, material is ready just for etching

- Material is hypoallergenic, suitable for contact with human skin

- Suitable for ring makers, watchmakers, jewelry makers, pen makers or artwork.

- Marking: “FF AUSTENITE”

- Hashtags: #StainlessFuturon #FFAUSTENITE

![]()

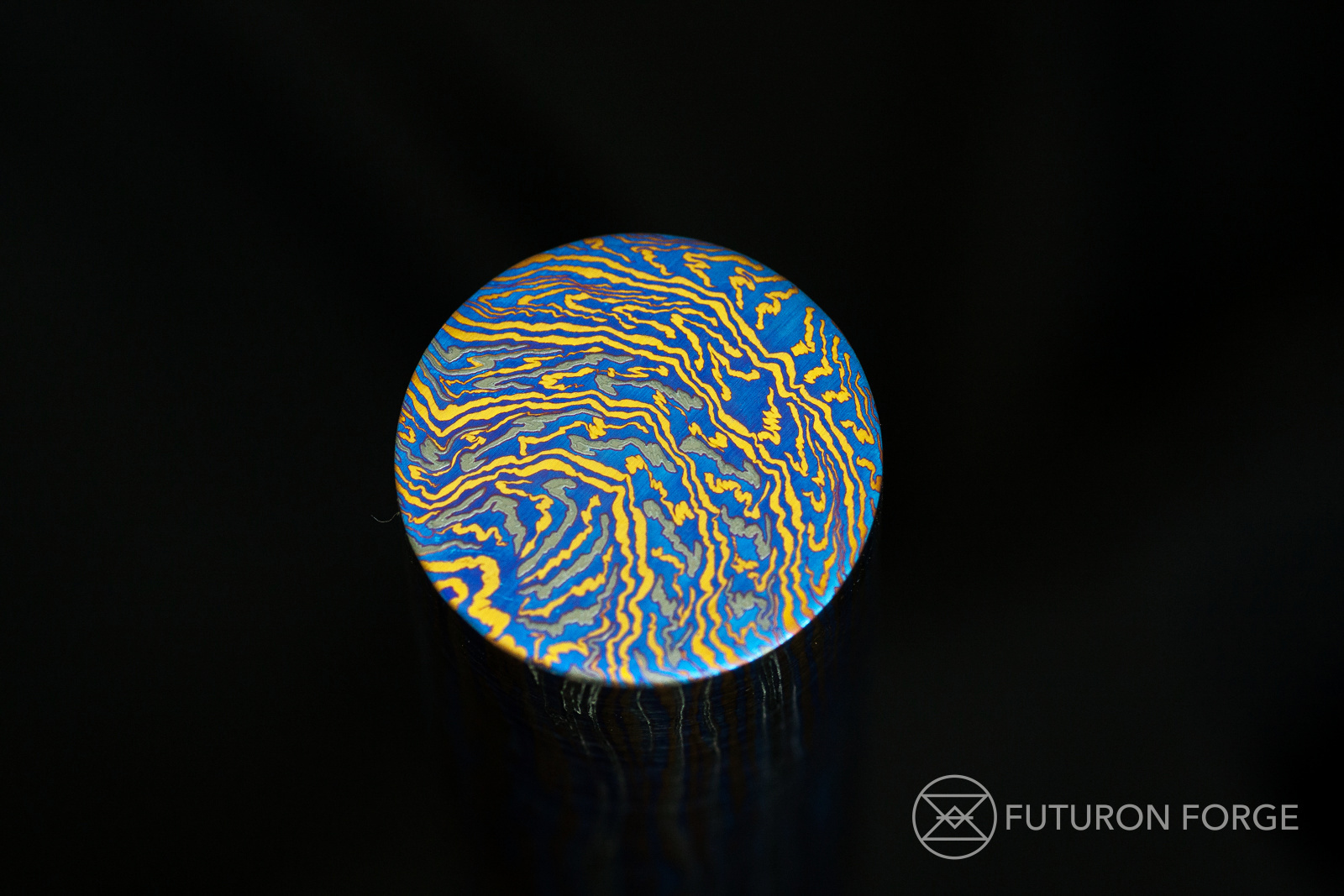

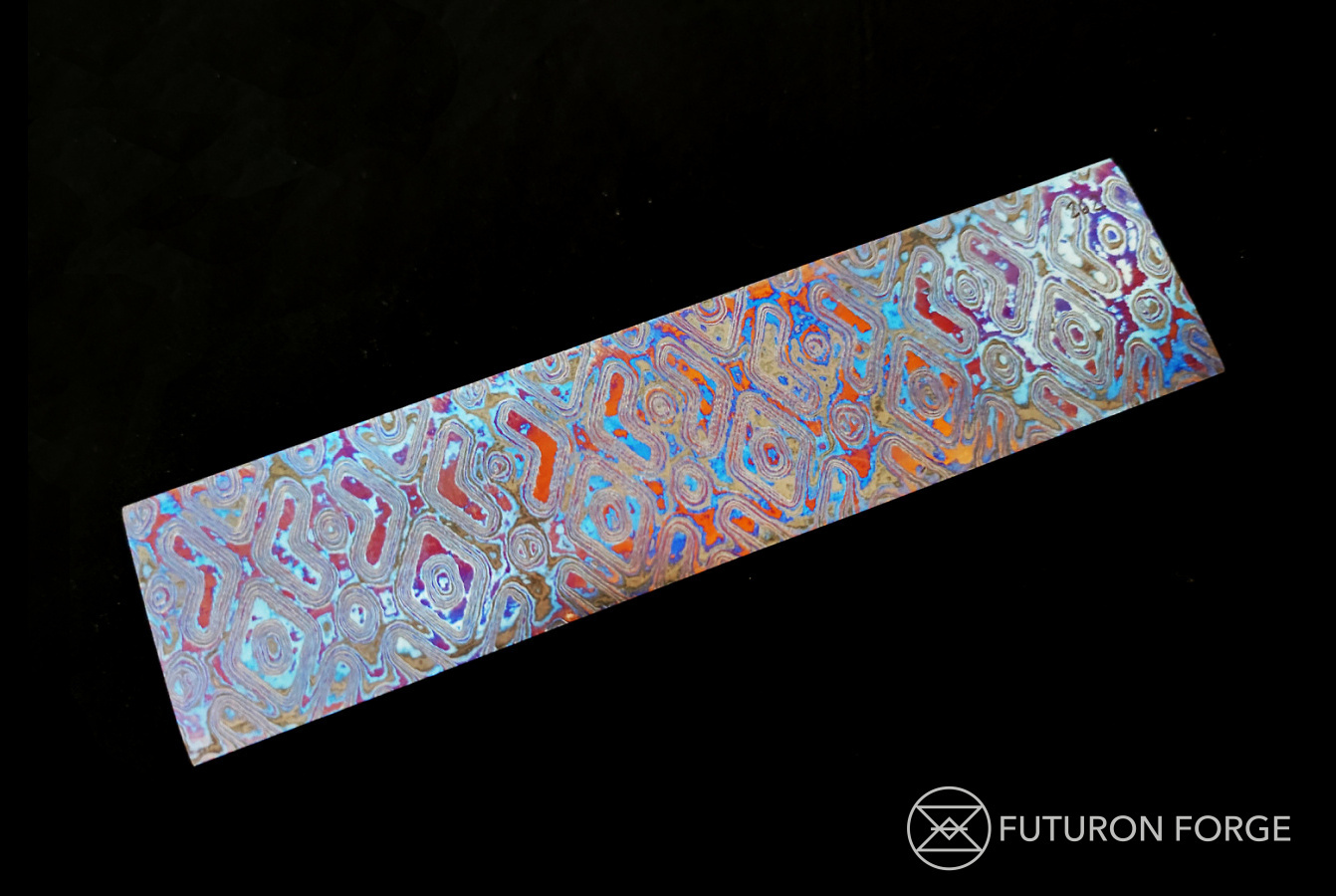

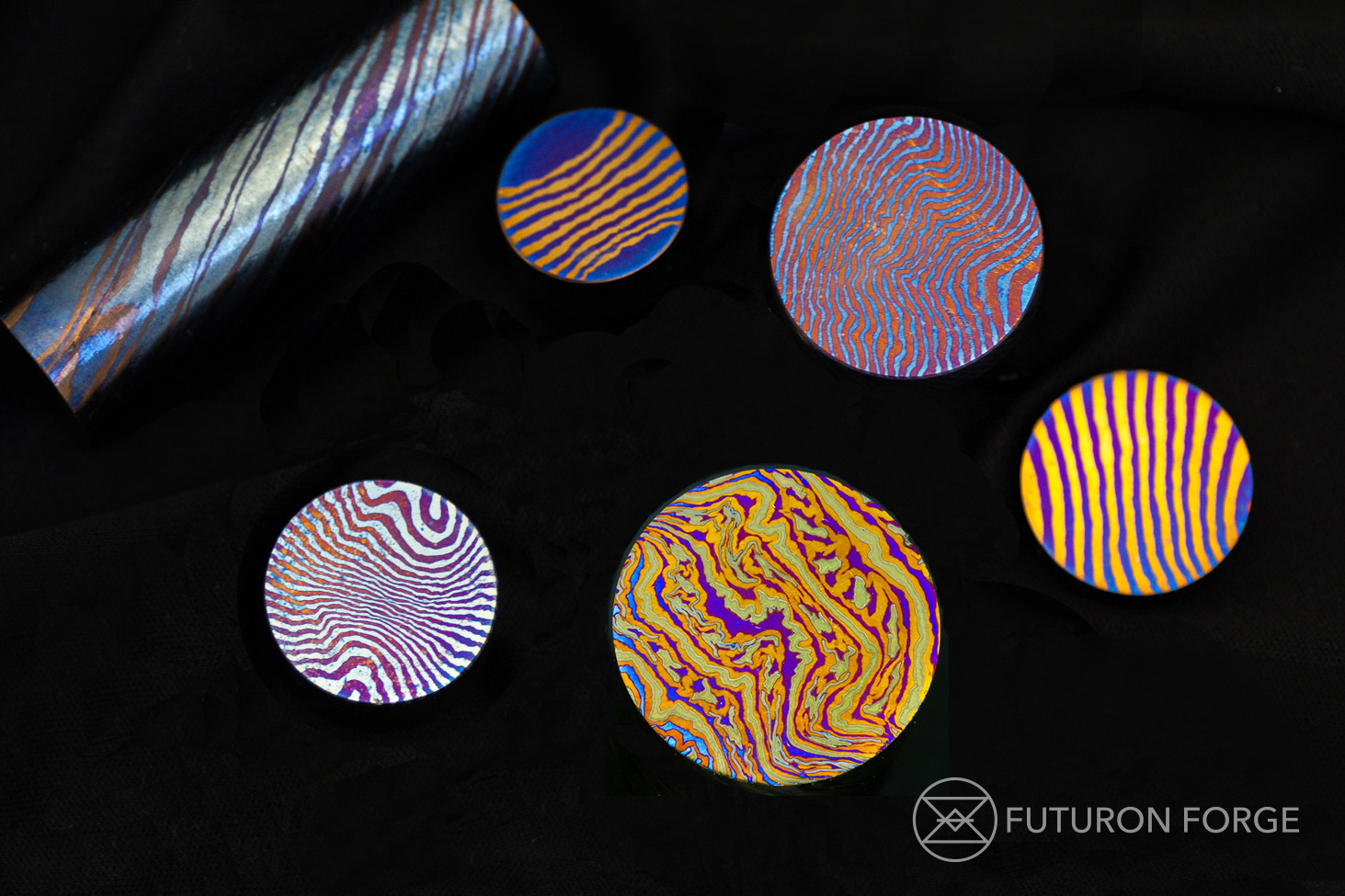

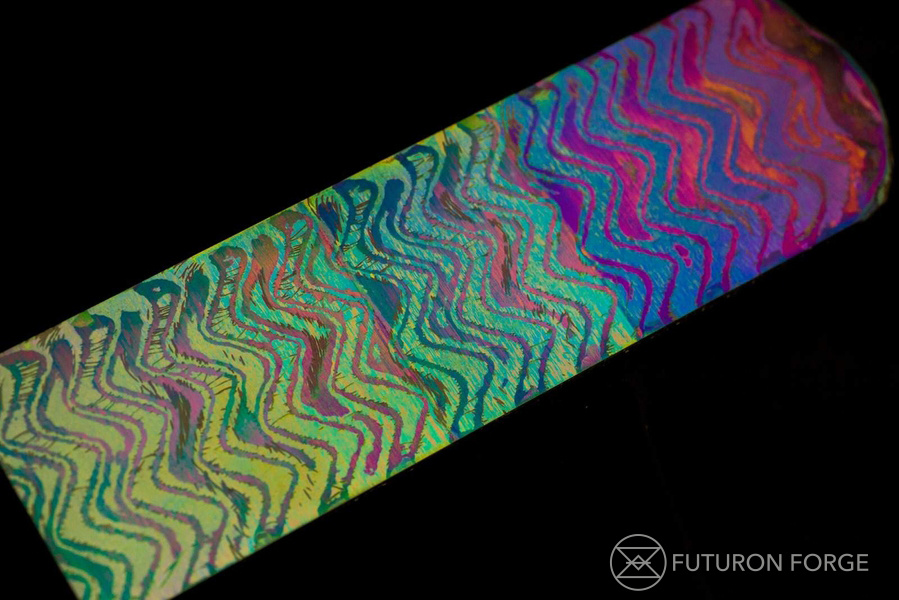

Rainbow

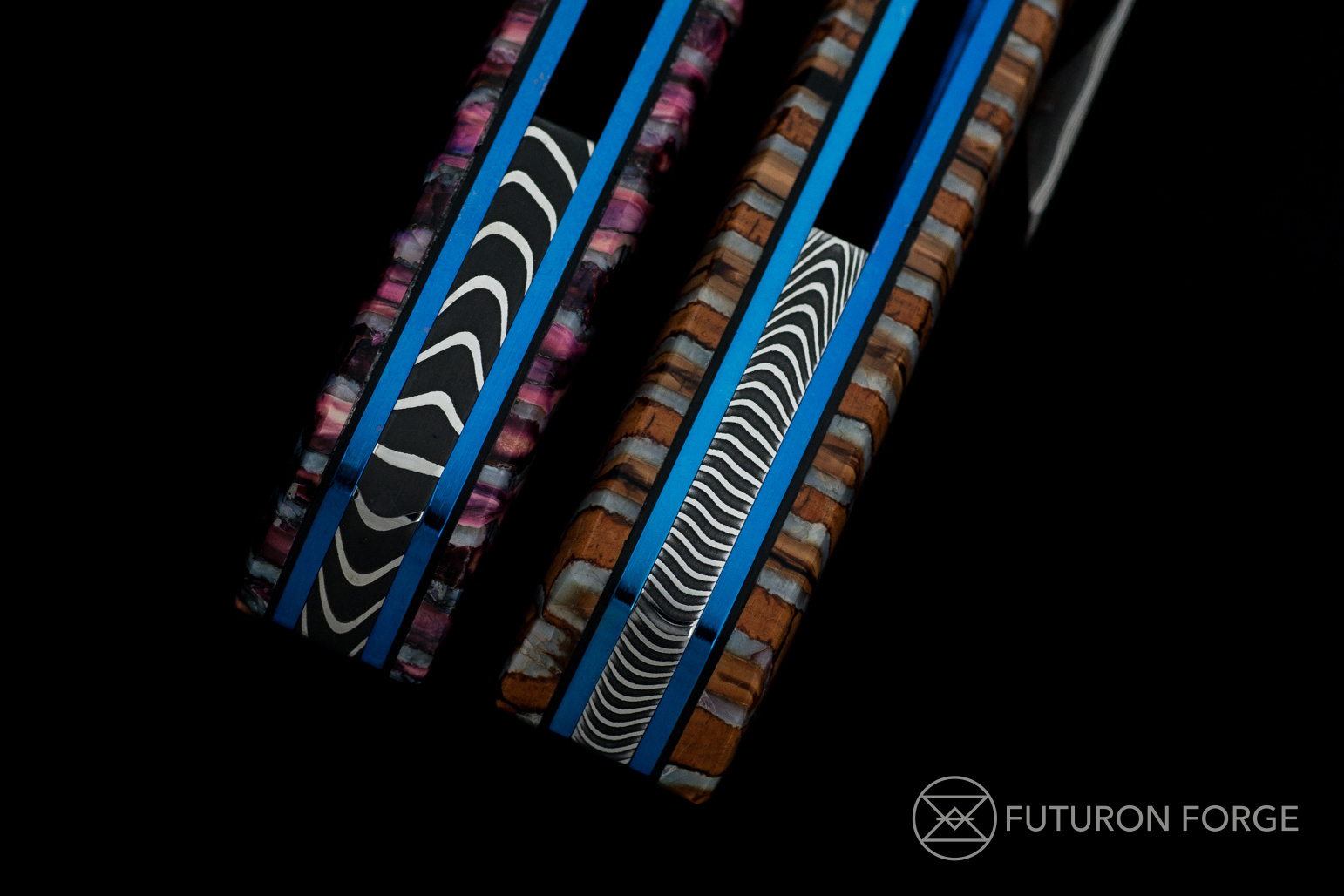

#RainbowFuturon is a damascus composite of various Titanium grades (Gr2, Gr5, Gr7 or Gr9) with Zirconium or Niobium. Our composites are hypoallergenic – suitable for contact with the human skin and highly corrosion resistant. Titanium composites even with Zirconium are relatively low-weighted. We produce this material in various shapes, layering, patterns, mainly flat bars, rods, or bolster mosaics.

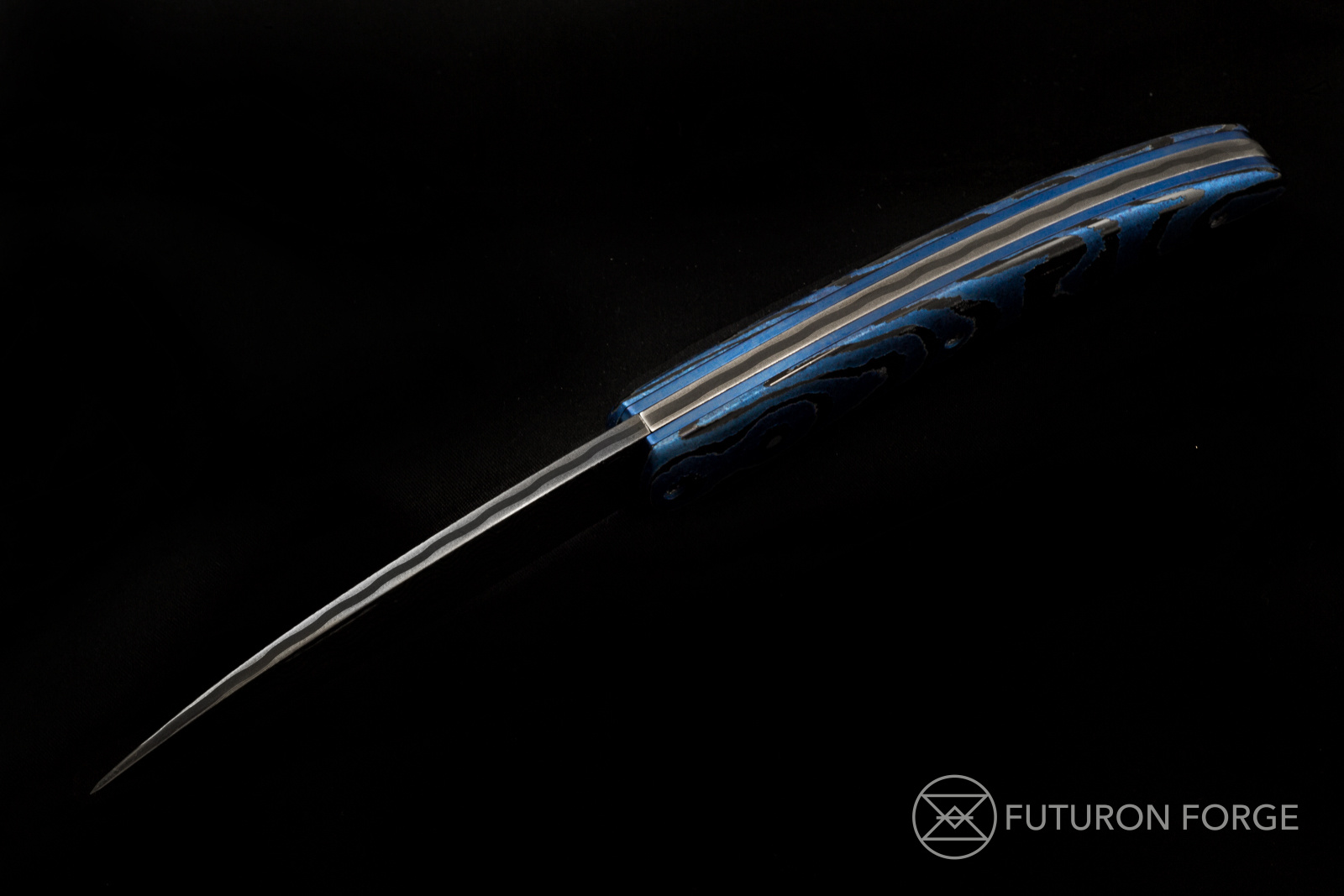

Rainbow-Zr

#Rainbow-Zr aka #BlackFuturon is Titanium-Zirconium damascus composite.

Zirconium – Zr – is a highly corrosion resistant element. Because of it’s unique properities is used in space, aeronautic and medical industries.

- Adding a black colour into the anodization colour spectrum

- You can reach different colours by electro-chemical or heat oxidation

- Each piece of produced material can be coloured differently

- Suitable for knife handle, knife hardware, jewelry applications, watchmaking or pen making

- Marking: “FF Rainbow-Zr”

- Hashtags: #BlackFuturon #Rainbow-Zr

![]()

Rainbow-Ti

#Rainbow-Ti is a composite of various Titanium grades. Titanium -Ti – is a strong, light metal.Because of it’s unique properities is used in aerospace, medical or jewelry industries. This composite has perfect mechanical properties, and it is rich in colour combinations.

- Composite of various Titanium grades (mainly Gr2, Gr5, Gr7, Gr9)

- You can reach different colours by electro-chemical or heat oxidation

- Each piece of produced material can be coloured differently

- Lightweight and fully-hypoallergenic

- Suitable for knifemaking, jewelry applications, watchmaking, or pen making

- Marking: “FF Rainbow-Ti”

- Hashtags: #RainbowFuturon #FFRainbow-Ti #Rainbow-Ti

![]()

Rainbow-Nb

#RainbowNb is a composite of Niobium and Titanium, sometimes even with Zirconium. Niobium – Nb – is a rare element, used for its properties in medicine, rocket engines, superalloys, etc. Composite of Niobium and various Titanium grades (mainly Gr2, Gr9).

- You can reach different colours by electro-chemical or heat oxidation

- Niobium brings another color into the color mix

- Each piece of produced material can be coloured differently

- Lightweight and hypoallergenic

- Suitable for knifemaking, jewelry applications, watchmaking, or pen making

- Marking: ” FF Niobium-Ti”

- Hashtags: #RainbowFuturon #FFNiobiumTi

![]()

Address

Futuron Forge s.r.o.

EU – Czech Republic

Tržiště 372/1

118 00 Praha

IČ: 08244189

DIČ: CZ08244189