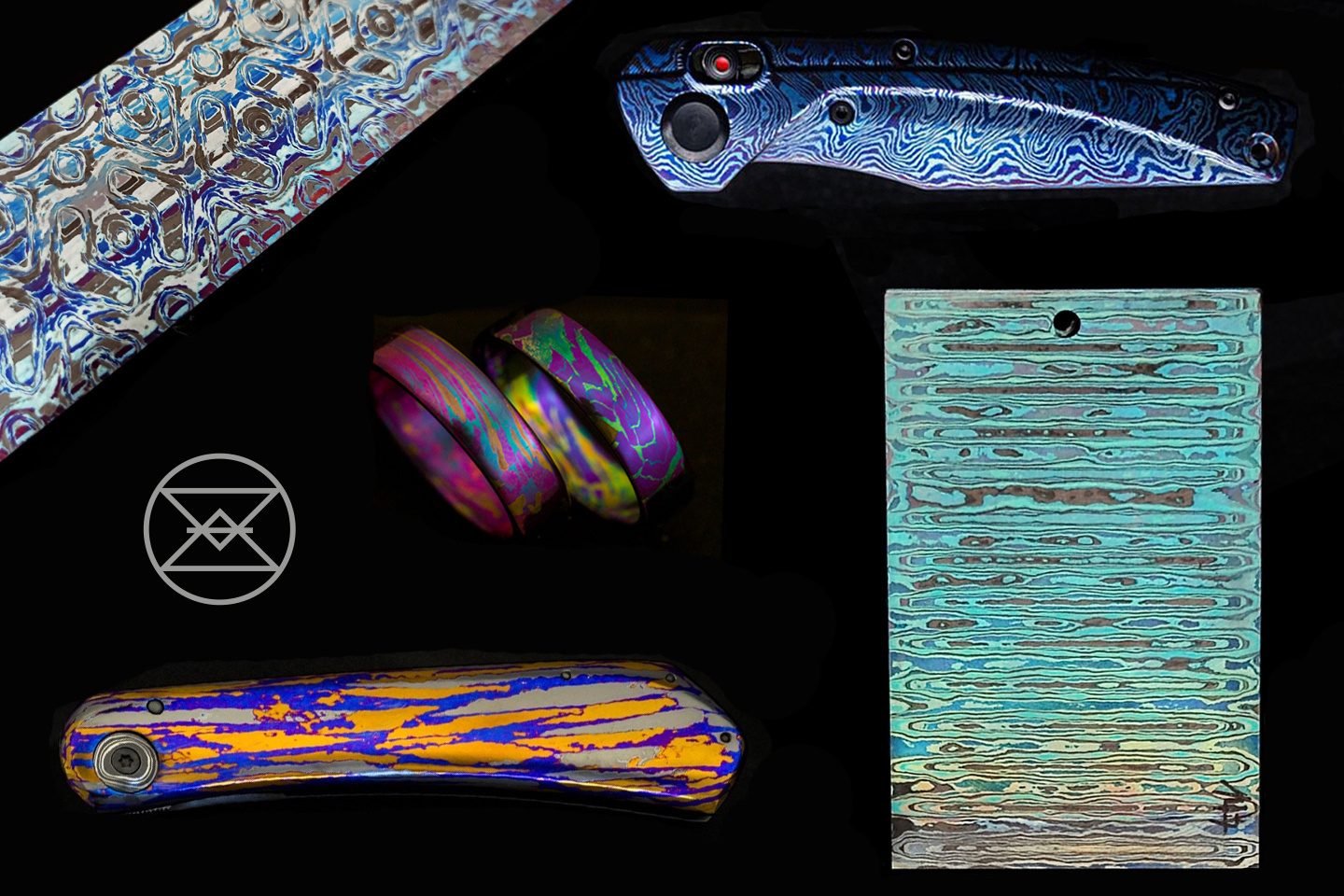

Stainless damascus -Titanium composites

Stainless damascus

Titanium composites

Key focus area

We produce stainless damascus steel and Titanium composites.

Our flagship product boasts stainless damascus steel with MagnaCut, ELMAX, or CPM154 core.

We have three general product groups: HardCORE (cored stainless damascus), Stainless (classic stainless damascus), and Rainbow Futuron (Titanium composites).

We provide premium quality for knifemakers, watchmakers, jewelry makers, pen makers, and other artists.

We systematically assess our processes through metallography analyses to deliver top-tier steel composites.

We produce billets in 3.1 – 8 mm (.125 – .310 in) thickness and rods in ø 18-45 mm (.70 – 1.7 in) diameter. For a production of our stainless steel and composites, we use premium powder steels from Bohler Uddeholm like ELMAX and VANAX, Crucible MagnaCut, CPM154, or fine martensititc steel like AEB-L, UHB-716 and various grades of Titanium and Zirconium. All our materials are soft annealed for easy processing.

Address

Futuron Forge s.r.o.

EU – Czech Republic

Tržiště 372/1

118 00 Praha

IČ: 08244189

DIČ: CZ08244189

[instagram-feed feed=1]