Technical Information – FF MARTENSITE

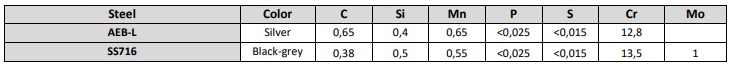

Composition

FF MARTENSITE is a martensitic high-performance stainless damascus composed of Uddeholm AEB-L + SS716 steels. AEB-L is stainless steel with a fine structure developed for razors and surgical scalpel production. Uddeholm SS716 has good corrosion resistance, excellent toughness, and fatigue properties. This material is intended for high-end knives or razors.

Forging

Generally, we do not recommend further forging of our damascus steel. This may lead to the destruction of steel fine grain structure and loss of its properties. However, if there’s a need to forge, follow these instructions:

- The forging temperature is 950-1050 °C

- Forging must be done smoothly to avoid the creation of cracks.

- Forged steel is very durable, so forging is more difficult in comparison with usual carbon steels.

- Slow cooling is necessary after the forging process.

- The forged piece has to be properly annealed.

Machining conditions

Our products are soft annealed to provide the best possible machining, reaching hardness approx. 280HV. You can use all conventional types of machining. We don’t recommend cutting (format) material on machine shears. We recommend bandsaw cutting, milling, laser, or waterjet cutting.

- Milling – monolithic carbide mill — Vc50-60 m/min

- For hard-milling (sizing) with monolithic carbide, mill feed up to Vc100 m/min

- Milling with VBD mill — Vc75-100 m/min

- Milling with HSS-Co mill — Vc14-16 m/min

- Drilling – HSS-Co drill — Vc10-12 m/min

- Drilling – PVD coated carbide drill —Vc60-80 m/min.

Grinding

You can grid our steel on all conventional types of grinders. We recommend belt-grinders or Berger grinding machines. For belt grinders, we recommend sanding belts with ceramic grains, like 3M Cubitron II; however, all ranges of conventional abrasives are usable (for example, SAIT, Klingspor, Norton, VSM, etc.). Watch out for not overheating (tempering) the steel by grinding. When it’s heat-treated, it may lose the required properties.

Soft annealing Soft annealing– Heat the material in a furnace to 820 °C / 150°- H

- Our materials are soft annealed. You have to apply this process only after forging.

- Heat the material in a furnace to 820 °C / 1508°F

- Hold at the temperature for 4 hours at least

- Slow cooling in a furnace

- You can remove the steel from a furnace when the temperature drops below 380°C / 716°F

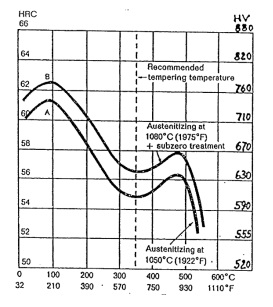

Hardening

Hardening is necessary to reach full corrosion resistance and the final hardness of the steel. We recommend hardening the steel by heat treatment professionals using vacuum technology like Bodycote. Recommended hardening process:

- Preheating temperature 1050-1080 °C / 1922-1976°F.

- Hold at the temperature for 15 minutes

- Cooling by nitrogen gas (oil cooling is also possible)

- Deep freeze -150/-196 °C / -302/-384 °F and hold for 1-3 hours. (optional process – increases hardness and durability of steel).

Tempering

After hardening, it’s necessary to begin the tempering process immediately.

We recommend tempering process 2 x 1h 150-180 °C / 302-356°F for knife blades . The final hardness is 60-61 HRc.

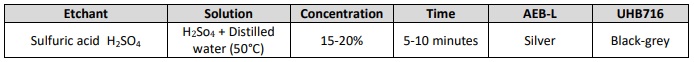

Etching

To properly contrast the damascus steel layers, it’s necessary to etch the material (blade). You can experiment with various etching techniques depending on your skill; however, following the below-mentioned steps, you’ll get nice results.

- Ensure that the blade’s surface is smooth, clean, and free of scratches (since etching won’t hide them), finished up to 1000+ grit or polished.

- Properly degrease the blade; cleaning it in the soap-water works well.

- Before etching, we recommend testing the solution on a sample piece of heat-treated material.

- You can reuse etching solution several times. Before you get the blade into the solution, check if there’s no dirt on the solution’s surface.

- After etching, you have to neutralize the blade using Na₂CO₃ (Sodium carbonate) or NaHCO₃ (Baking soda). You can also use soap water and properly clean the etching residues from a blade.

- Dry the etched blade. We recommend spraying the blade with WD-40 (or similar) and drying it again to remove any possible residues.

- You can slightly polish the etched blade on a buffing wheel with sandpaper with 2000+ grit for better contrast. We recommend testing it on a sample piece.

- Warning: using other etchants (like Fe3Cl) or non-compliance with the etchants heating procedure (50 – 60°C) leads to poor results.

Marking

FF MARTENSITE

@futuronforge #stainlessFuturon #FFMARTNSITE

Adresa

Futuron Forge s.r.o.

EU – Czech Republic

Krymská 517/50

460 06 Liberec 6

IČ: 08244189

DIČ: CZ08244189

Sledujte nás

[instagram-feed]