Technical Information – FF AUSTENITE

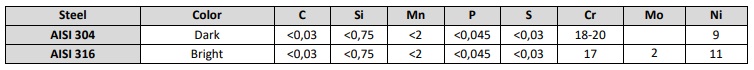

Composition

FF AUSTENITE is a stainless damascus composed of two austenitic (non-hardenable) steels AISI 304 + AISI 316. Both steels have low Nickel (Ni) volume, making them hypoallergenic. This material is suitable for jewelry, watchcases, or artwork production.cterized by their low volume of nickel (Ni), so they can be considered hypoallergenic.

Forging

Generally, we do not recommend further forging of our damascus steel. This may lead to the destruction of steel fine grain structure and loss of its properties. However, if there’s a need to forge, follow these instructions:

- Forging temperature is 950-1160°C / 1742-2120°F.

- To avoid possible cracks, do not forge in temperature under 940°C / 1724°F.

- Forging has to be done smoothly to prevent the creation of cracks.

- Forged steel is very durable, so forging is more complicated in comparison with usual carbon steels.

- Slow cooling is necessary after the forging process.

- We recommend using a controlled electric furnace with a protective atmosphere; however, a propane gas forge also works.

Machining conditions

You can use all conventional types of machining. We don’t recommend cutting (format) material on machine shears. We recommend bandsaw cutting, milling, laser or waterjet cutting.

- Milling – monolithic carbide mill — Vc80-120 m/min

- Milling with VBD mill — Vc95-130 m/min

- Milling with HSS-Co mill — Vc25 m/min

- Drilling – HSS-Co drill — Vc23 m/min

- Lathing with VBD — Vc80-120 m/min.

Grinding

You can grid our steel on all conventional types of grinders. We recommend belt-grinders or Berger grinding machines. For belt grinders, we recommend sanding belts with ceramic grains, like 3M Cubitron II; however, all range of conventional abrasives is usable (for example, SAIT, Klingspor, Norton, VSM, etc.). Watch out for not overheating (tempering) the steel by grinding. When it’s heat-treated, it may lose the required properties.

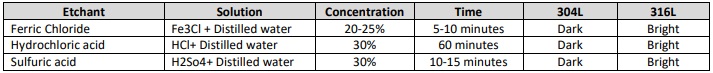

Etching

To properly contrast the damascus steel layers, it’s necessary to etch the material (blade). You can experiment with various etching techniques depending on your skill; however, following the below-mentioned steps, you’ll get nice results.

- The blade’s surface has to be smooth, clean, without scratches (etching won’t hide it), finished up to 1000+ grit or polished.

- The blade has to be properly degreased (cleaning in the soap-water works fine).

- Before you start etching, try the solution on a sample piece of material (heat-treated).

- You can reuse the etching solution several times. Before you get the blade into the solution, check if there’s no dirt on the solution’s surface.

- When the etching is finished, you have to neutralize the blade using Na₂CO₃ (Sodium carbonate) or NaHCO₃ (Baking soda). You can also use soap and water and properly clean the etching residues from a blade.

- Dry the blade. We recommend spraying the blade with WD-40 (or similar) and drying it again to remove any residues.

- For better contrast, you can slightly polish the etched blade on a buffing wheel. We recommend testing it on a sample piece.

- You can enhance the contrast by using the propane torch and then slight hand-grinding by sandpaper with 2000+grit. We recommend testing it on a sample piece.

- If you want to make your etching solution more reactive, increase the concentration of Fe3Cl or add vinegar.

Marking

FF AUSTENITE

@futuronforge #stainlessFuturon #FFAustenite

Adresa

Futuron Forge s.r.o.

EU – Czech Republic

Tržiště 372/1

118 00 Praha

IČ: 08244189

DIČ: CZ08244189

Sledujte nás

[instagram-feed]